Save time while using 20% less horsepower

Using 20% less horsepower and requiring less time per mix than conventional mixers — a Jaylor mixer reduces fuel consumption and ensures a longer operating life.

The Jaylor 6850HD Twin Auger TMR Mixer is built for demanding commercial feeding operations, engineered to withstand continuous, all-day use with exceptional durability. Designed for large-scale production, it can process up to two 5×6 or four 4×5 round bales per load, handling approximately 1,740 kg of hay equivalent with ease.

With the capacity to feed up to 160 dairy cattle, 200 beef cows, or 800 adult sheep and goats per load, the 6850HD delivers a consistent, high-quality TMR to support optimal herd performance and operational efficiency.

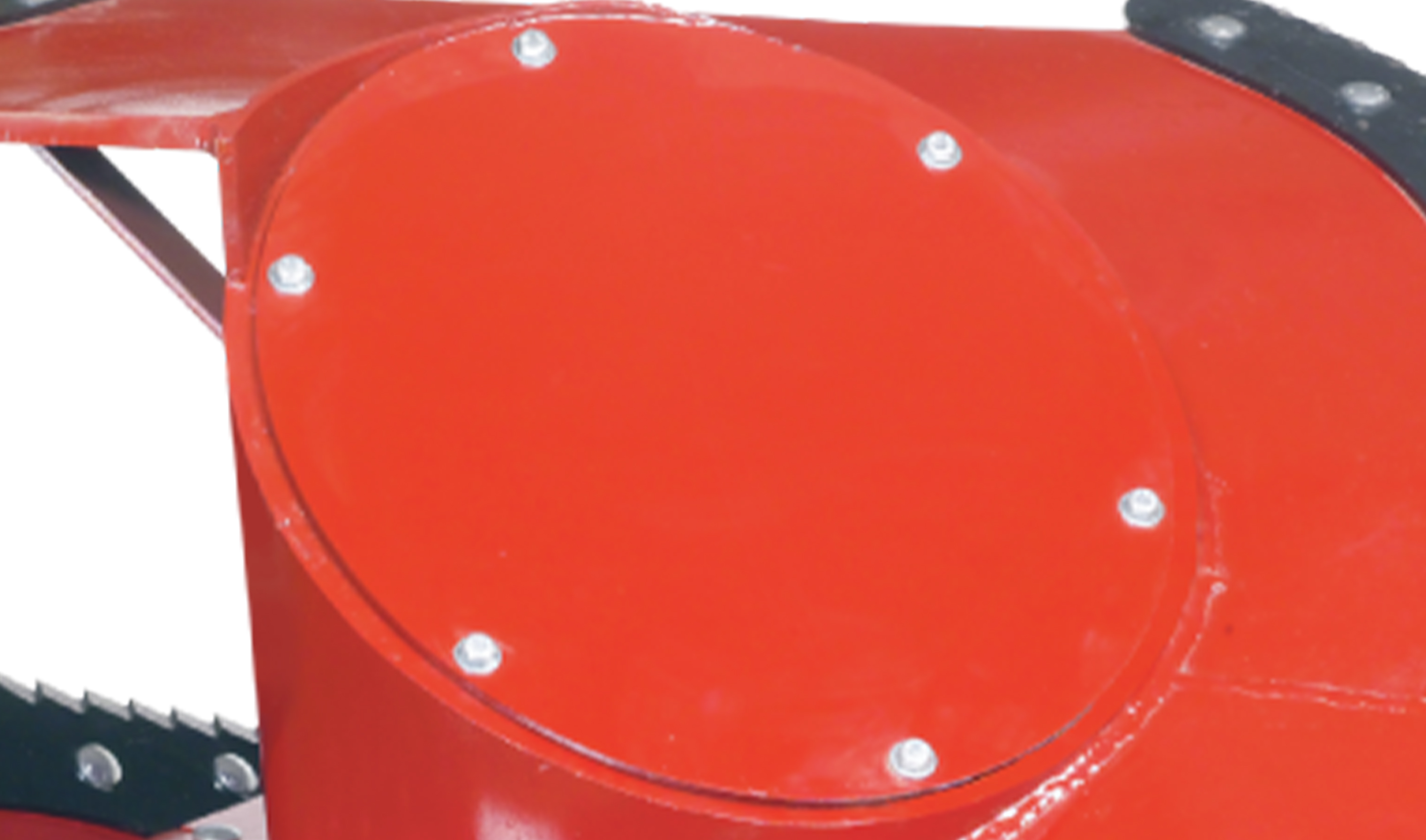

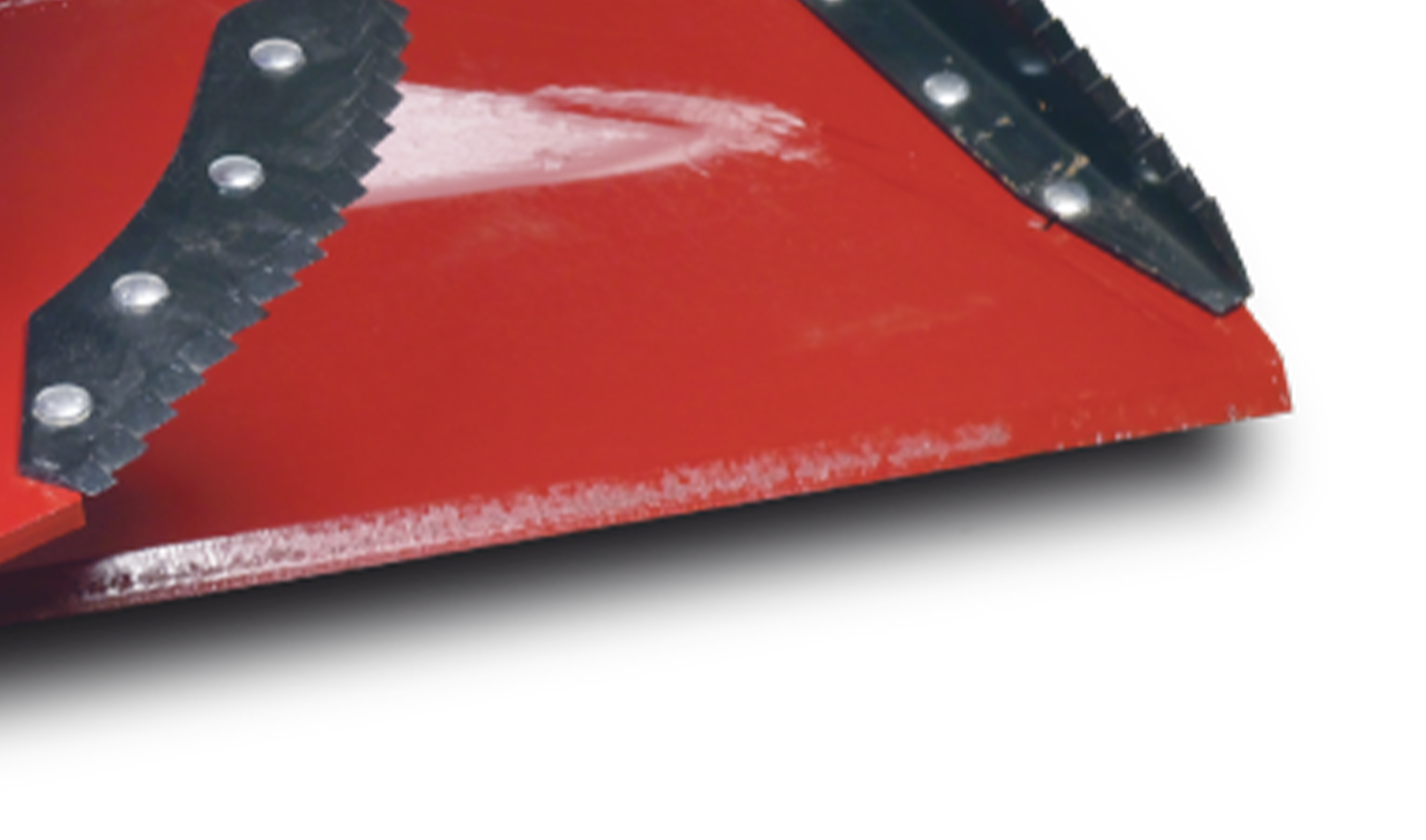

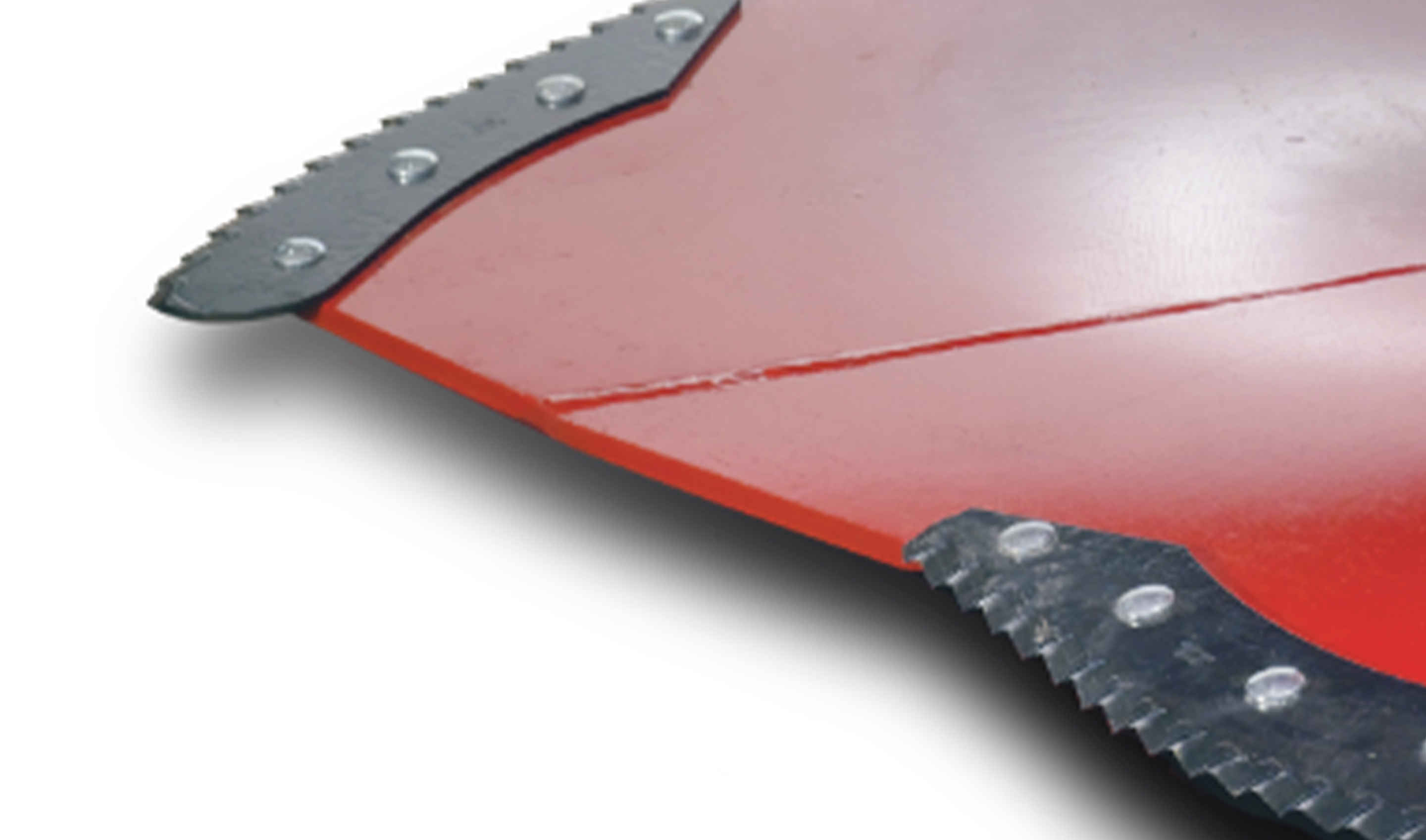

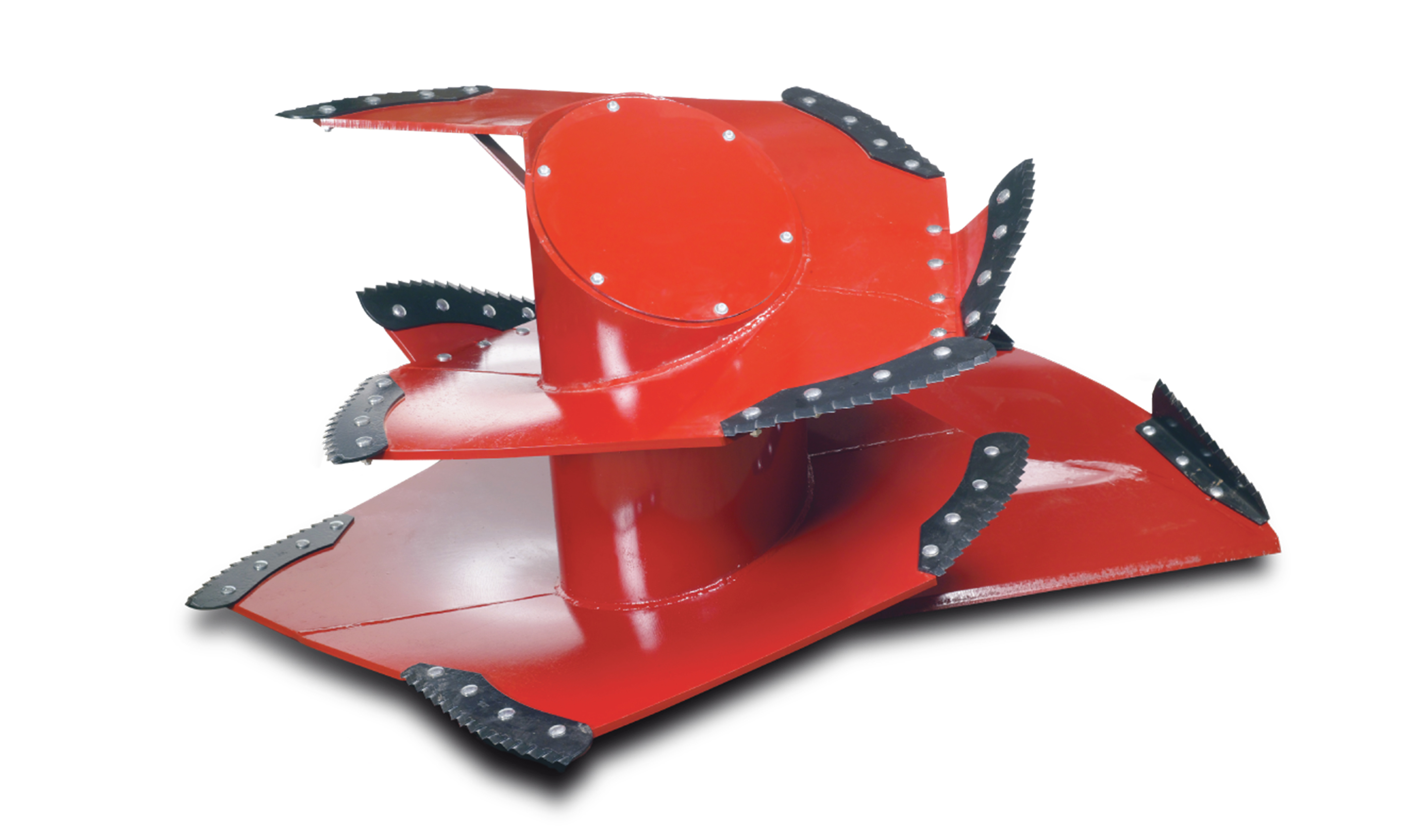

As part of the Heavy Duty series, the 6850HD features the upgraded HD specification — including a walking-beam axle for improved stability and flotation, and thicker ¾-inch auger flighting for increased strength and longevity in intensive feeding environments.

Using 20% less horsepower and requiring less time per mix than conventional mixers — a Jaylor mixer reduces fuel consumption and ensures a longer operating life.

Compare specifications below, to find out what will be suit your operations

| Models | Jaylor 6750 | Jaylor 6750HD | Jaylor 6850 | Jaylor 6850HD |

|---|---|---|---|---|

| Sort | Dual Auger | |||

| Horse Power | 115 | 125 | 135 | |

| Capacity No Extension | N/A | 22.7m3 | ||

| Capacity 8" EXTENSION | N/A | |||

| Capacity 12" extension | 21.0m3 | 25.8m3 | ||

| Capacity 16" extension | 22.1m3 | 27.2m3 | ||

| Weight | 5900kg | 6100kg | 8000kg | |

| Length | 737cm | 782cm | ||

| Height | 284cm | 305cm | 274cm | 305cm |

| Drum Width | 231cm | 246cm | ||

| PTO Speed | 1000 RPM | |||

| Auger Speed | 38 RPM | |||

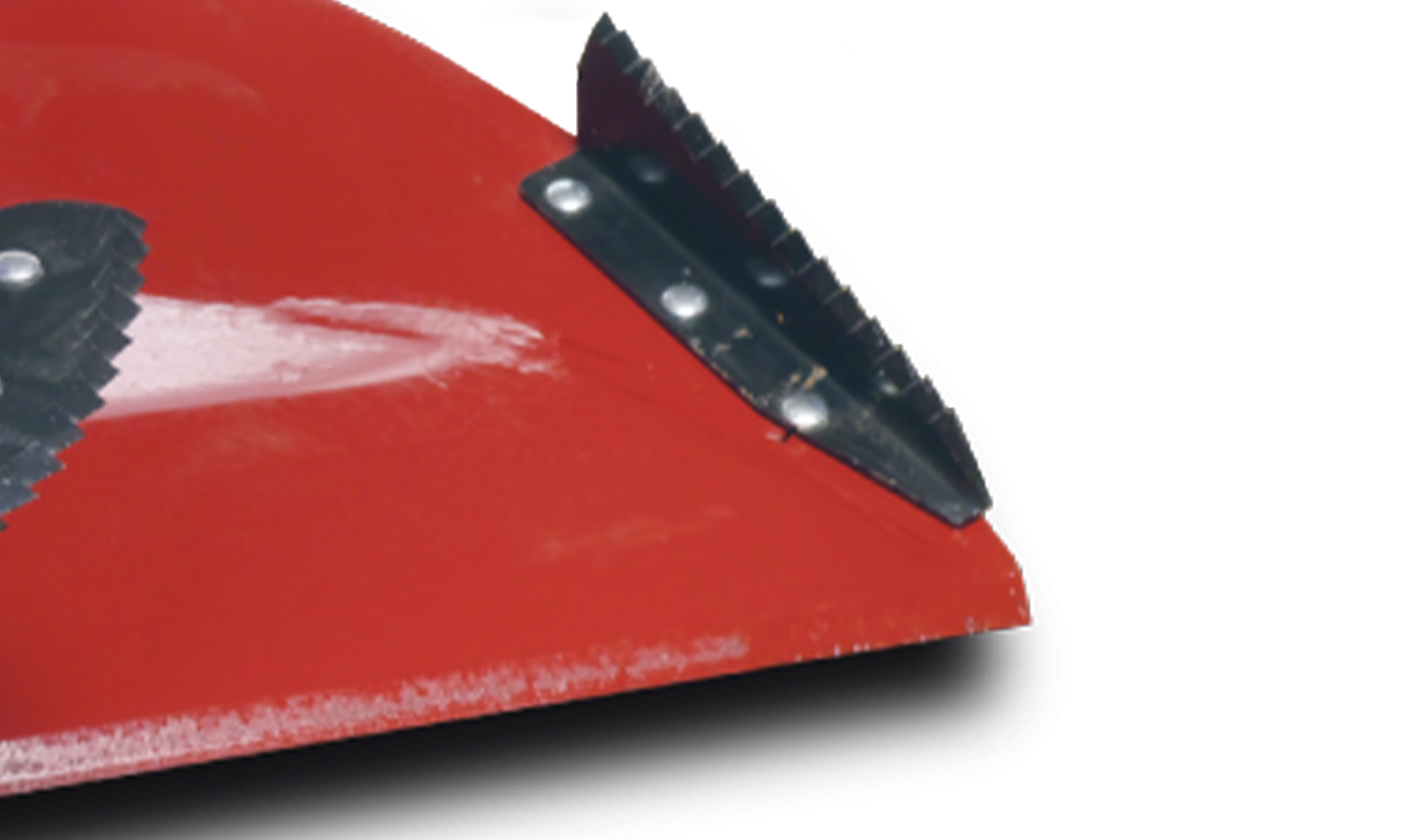

| Knives | 18 | |||

| Max. Discharge Height | 190cm | 201cm | 190cm | 203cm |

| Conveyor Width | 91cm | |||

| Door Opening Width | 107cm | |||

| Floor Thickness | 16mm | 19mm | ||

| Drum Wall Thickness | 6mm | 9mm *with included lower wall stainless steel liner | 6mm | 9mm *with included lower wall stainless steel liner |

| Standard Tyre | 15.0/55-17 26 Ply tyres (4) | 435/50R-19.5 Super Single tyres (4) | 15.0/55-17 26 Ply tyres (4) | 560/45R 22.5 BKT FL630 tyres (4) |

| Wheel Assembly | Dual Oscillating | Walking Beam | Dual Oscillating | Walking Beam |

| Compare | ||||