Save time while using 20% less horsepower

Using 20% less horsepower and requiring less time per mix than conventional mixers — a Jaylor mixer reduces fuel consumption and ensures a longer operating life.

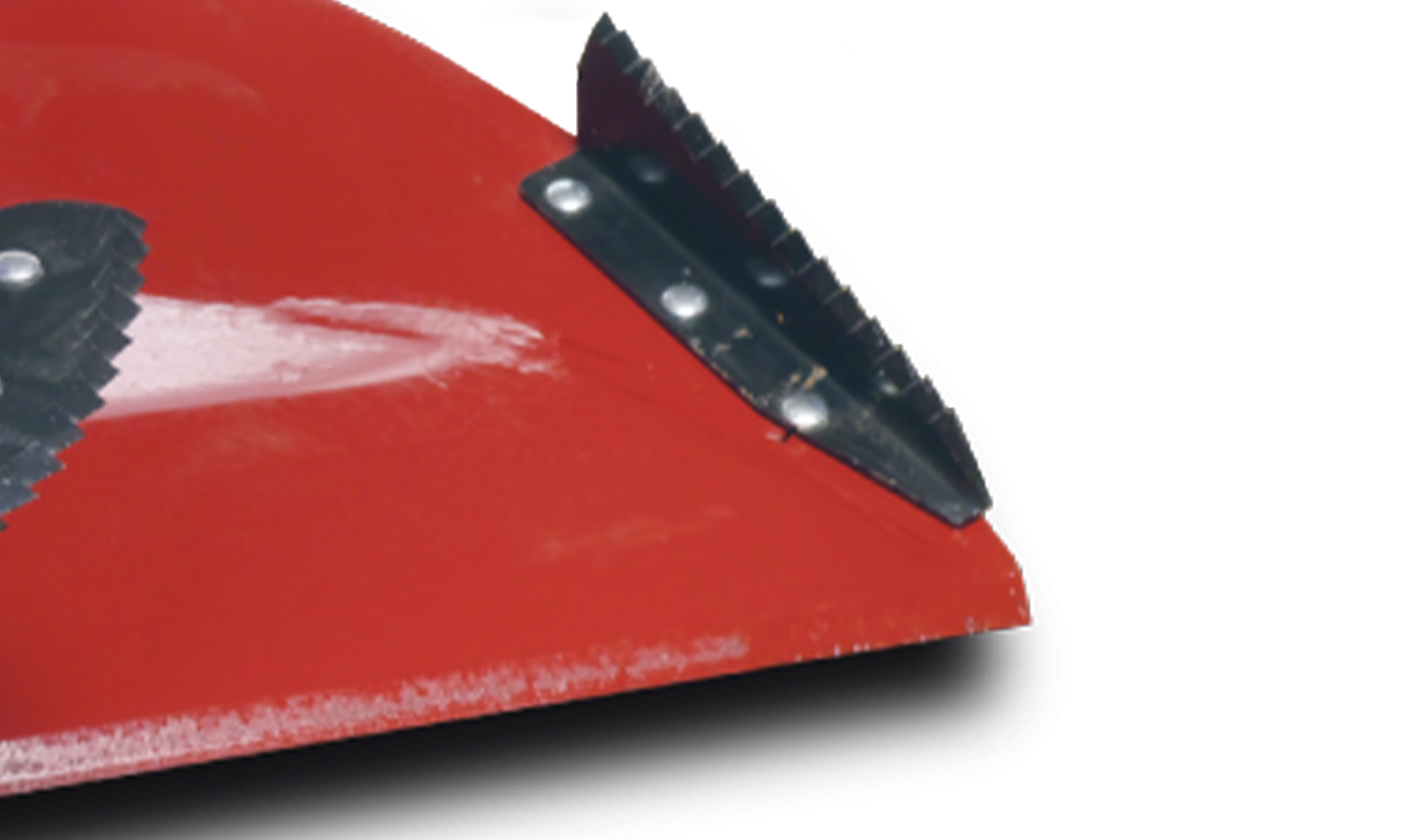

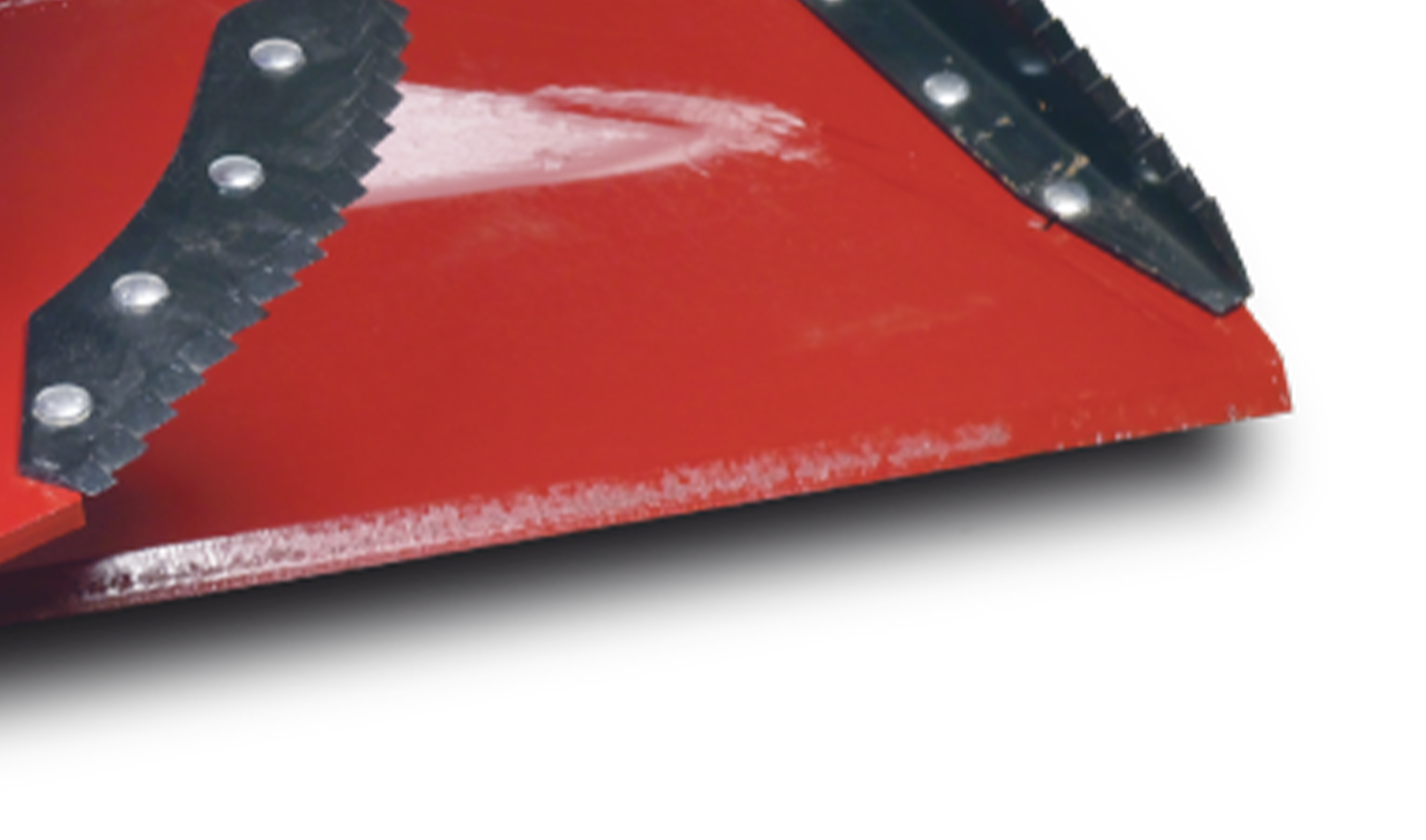

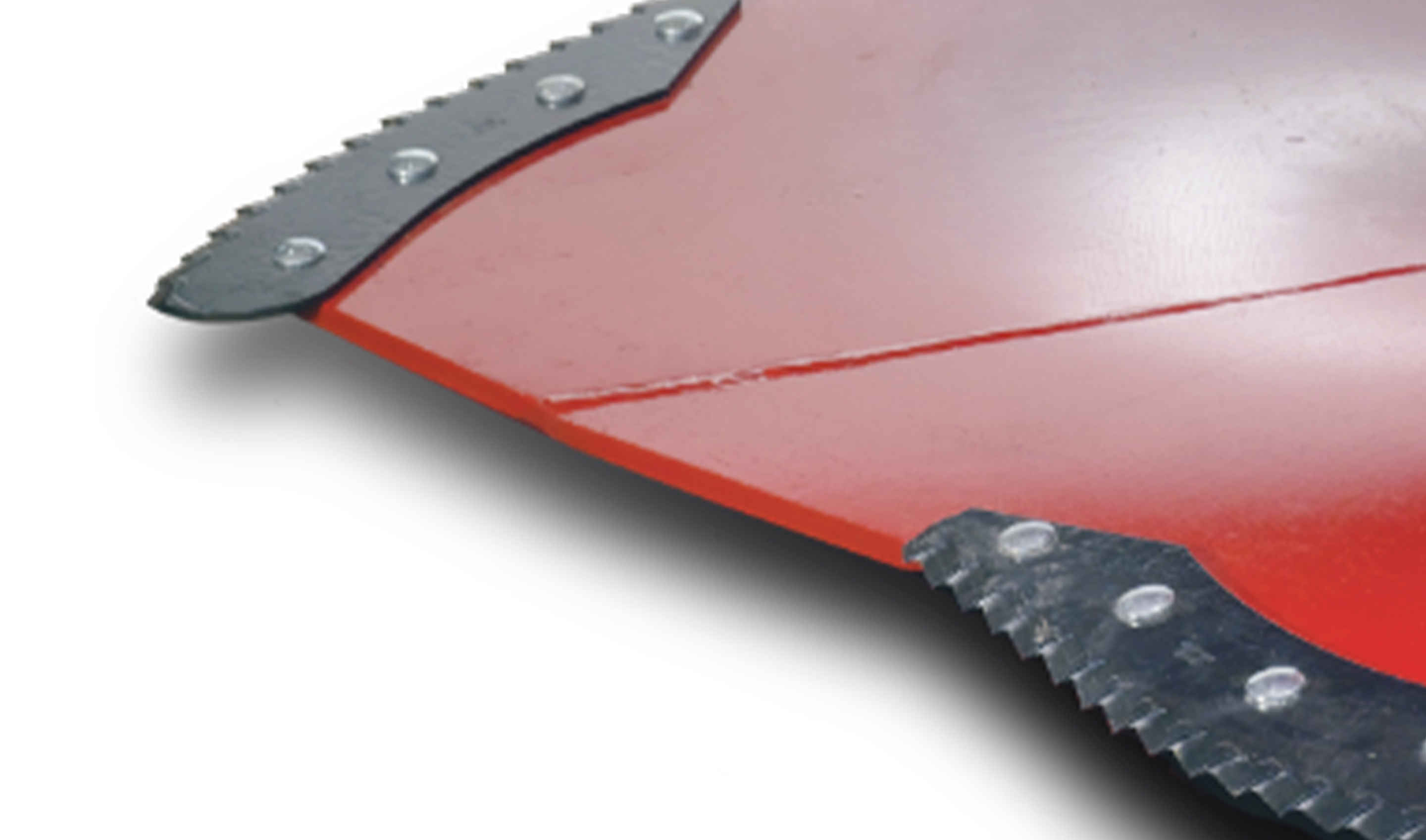

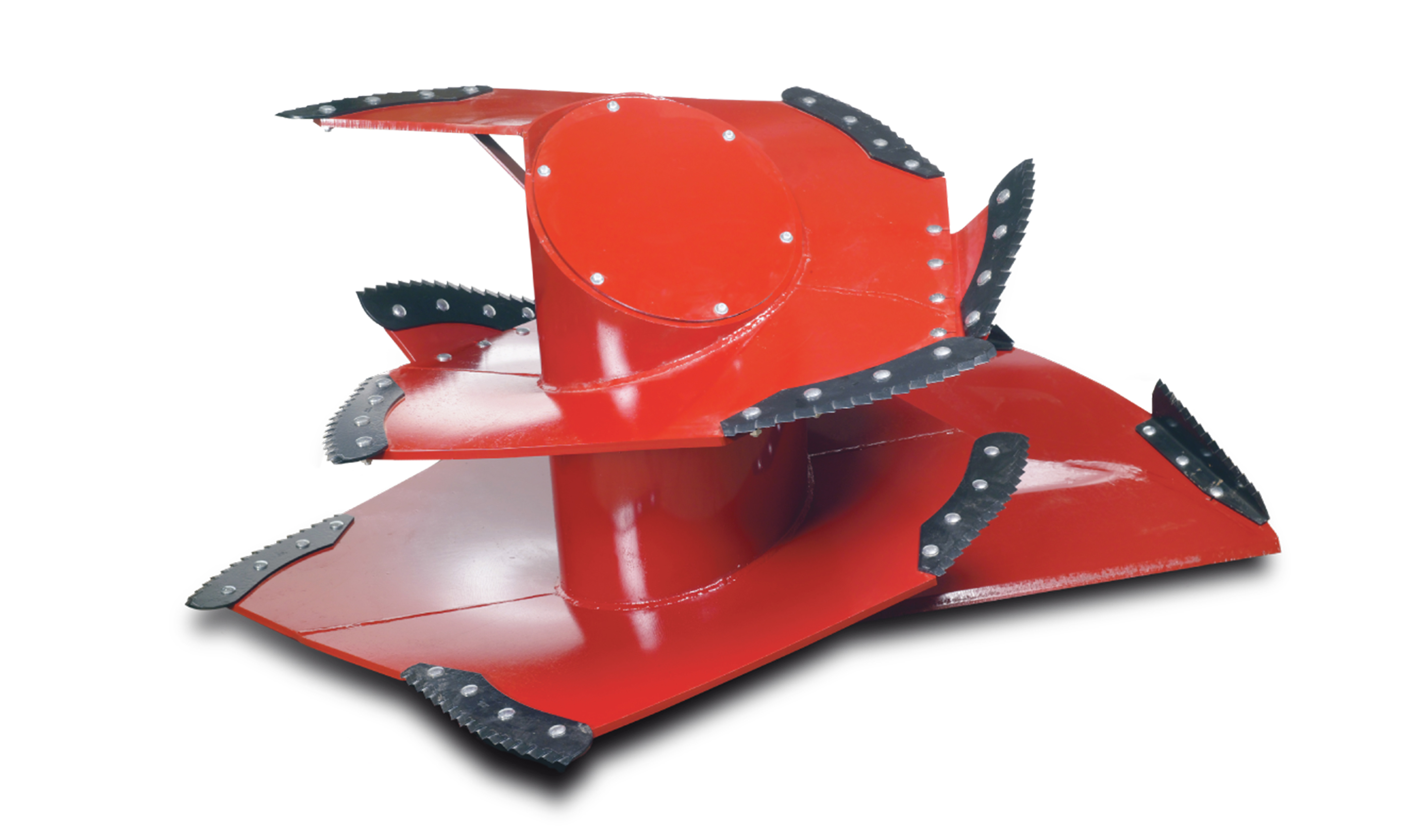

Jaylor’s Twin Auger mixers are engineered for farms that need fast, consistent feed processing with maximum efficiency. Featuring Jaylor’s patented square-cut auger design, these mixers deliver a uniform, fluffy TMR while reducing fuel use and mixing time. The twin-auger layout handles larger volumes with ease, improves vertical feed movement, and ensures even blending of all ingredients, from long fibre to finer supplements. Built tough and simple to maintain, Jaylor Twin Augers are a reliable choice for New Zealand operations looking for performance, durability, and low total cost of ownership.

The Jaylor 6750 twin-auger is a cost-effective mixer with 21 m³ capacity. It is built to a high specification and operates with a 1000 PTO rpm input, which helps reduce the load on the tractor.

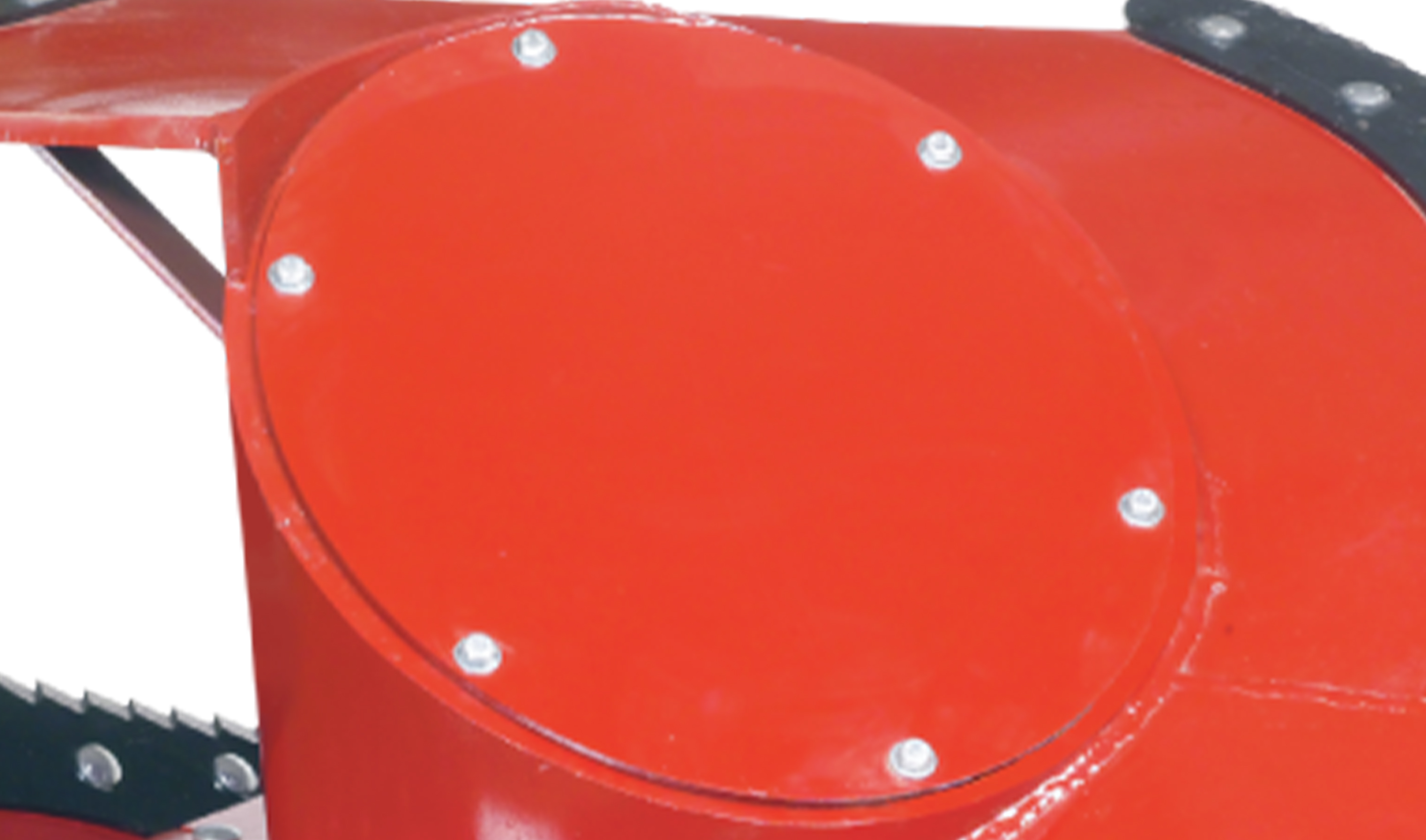

This unit also comes standard with the reduction start-up gearbox, combined with the higher input speed and the gearbox’s twin-reduction design, this allows the augers to maintain a steady 38 rpm. Fitted with reinforced 17-inch rims and 26-ply tyres, the mixer can handle a wet mixed load of over 11,000 kg across four wheels without strain.

The mixer rides on a twin-axle with centre oscillation, which helps smooth its travel over rough ground: this design reduces bowl pitching by over 50% when moving over nib walls. All the twin-auger machines in the range come with wide-angle Series 8 drive shafts. The empty weight of the unit is just 5,900 kg. The standard warranty package applies.

Using 20% less horsepower and requiring less time per mix than conventional mixers — a Jaylor mixer reduces fuel consumption and ensures a longer operating life.

Compare specifications below, to find out what will be suit your operations

| Models | Jaylor 6750 | Jaylor 6750HD | Jaylor 6850 | Jaylor 6850HD |

|---|---|---|---|---|

| Sort | Dual Auger | |||

| Horse Power | 115 | 125 | 135 | |

| Capacity No Extension | N/A | 22.7m3 | ||

| Capacity 8" EXTENSION | N/A | |||

| Capacity 12" extension | 21.0m3 | 25.8m3 | ||

| Capacity 16" extension | 22.1m3 | 27.2m3 | ||

| Weight | 5900kg | 6100kg | 8000kg | |

| Length | 737cm | 782cm | ||

| Height | 284cm | 305cm | 274cm | 305cm |

| Drum Width | 231cm | 246cm | ||

| PTO Speed | 1000 RPM | |||

| Auger Speed | 38 RPM | |||

| Knives | 18 | |||

| Max. Discharge Height | 190cm | 201cm | 190cm | 203cm |

| Conveyor Width | 91cm | |||

| Door Opening Width | 107cm | |||

| Floor Thickness | 16mm | 19mm | ||

| Drum Wall Thickness | 6mm | 9mm *with included lower wall stainless steel liner | 6mm | 9mm *with included lower wall stainless steel liner |

| Standard Tyre | 15.0/55-17 26 Ply tyres (4) | 435/50R-19.5 Super Single tyres (4) | 15.0/55-17 26 Ply tyres (4) | 560/45R 22.5 BKT FL630 tyres (4) |

| Wheel Assembly | Dual Oscillating | Walking Beam | Dual Oscillating | Walking Beam |

| Compare | ||||