McHale F5-560 Plus

The McHale F5-560 PLUS is a fully automatic Fixed Chamber Baler equipped with load sensing hydraulics and a 25 knife chopper unit.

It is equipped with a film binding system that applies film to the barrel of the bale in the bale chamber. For hay or straw, net can be used. The McHale patented film application system ensures consistent film stretch, reliable film application and delivers optimum bale shape and bale density. The machine is fitted with 500/50-22.5 tyres as standard.

McHale have developed various types of pick-ups. After extensive testing, McHale decided it would offer customers the choice of 2 pick-up options depending on their conditions:

Cam Pick-Up – Optional indent order only

As standard, a cam operated 2.1 m high-intake galvanised pick-up ensures excellent ground cleaning in all types of crop. The cam pick-up runs on a cam track that is fitted with double raced cam bearings to stand up to the most testing of conditions.

All pick-ups across the McHale variable chamber baler range are fitted with 5 tine bars for excellent delivery of crop to the bale chamber. The 2.1 metre galvanised pick-up will lift even the shortest of crop. A side inspection port allows the operator to quickly check and change the cam bearings.

Camless Pick-Up

A 2.1 m camless pick-up is available as an option on all machines in the variable chamber baler range. Six tine bars are fitted to all McHale camless pick-ups to provide excellent ground cleaning and fast delivery of crop to the chamber. The new camless pick-up has been designed for increased output, with that in mind the cam-track free pick-up is more reliable, consists of less moving parts and is maintenance free.

All McHale pick-ups come with a number of standard features that include:

Heavy Duty Pick-up

All McHale pick-ups feature heavy-duty tine bar supports to ensure long service life. A vital part of the pick-up is the tine, McHale have developed a pick-up tine designed to lift even the shortest of crop.

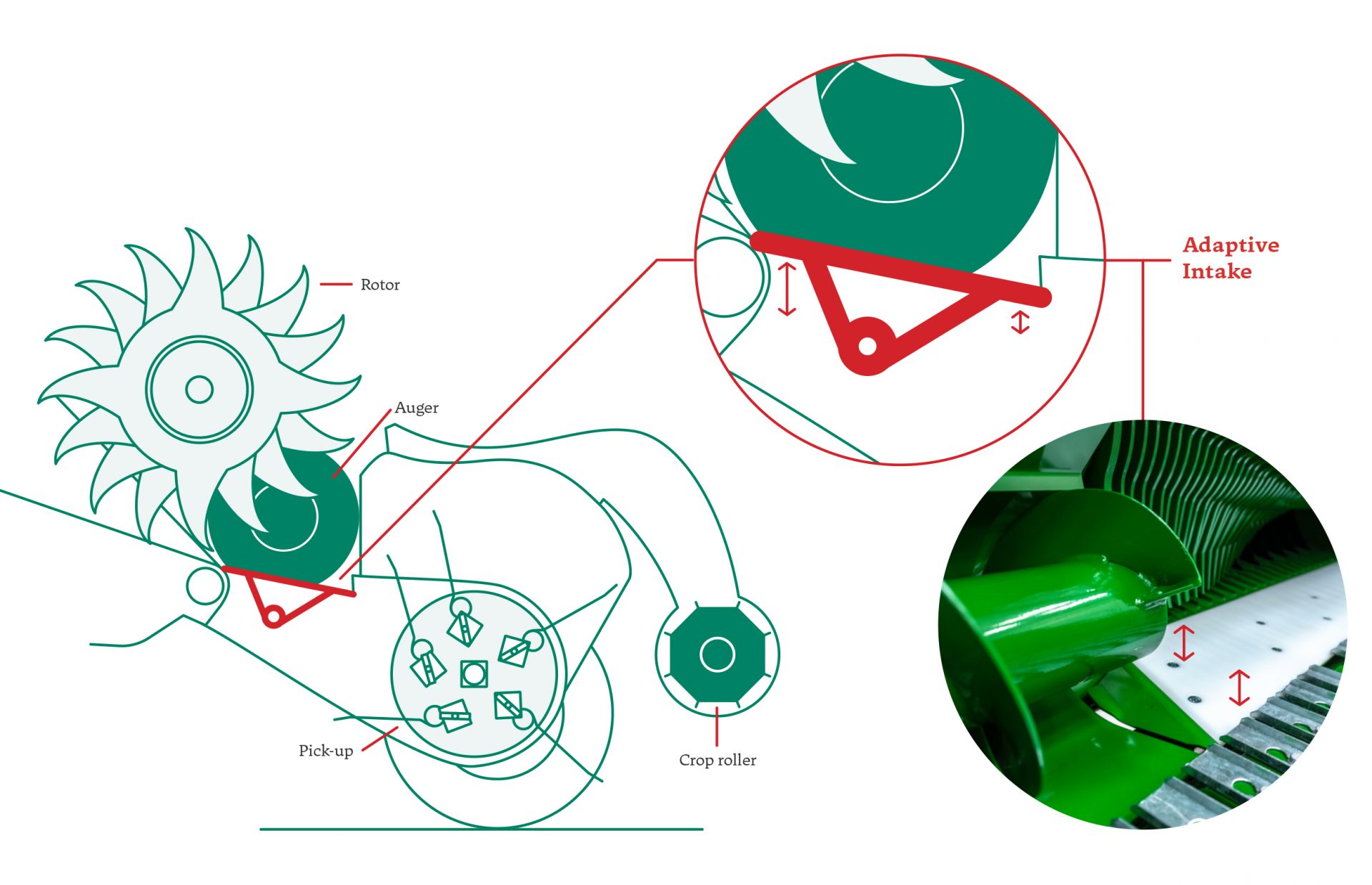

Efficient Crop Flow Delivery

The specially designed McHale pick-up is positioned close to the rotor to improve delivery of the crop through the rotor to the bale chamber. Large diameter lateral feed augers help direct crop to the bale chamber ensuring a consistent and even crop flow for producing high density bales.

Adaptive Intake

Over the course of a baling season, machines have to work with different volumes of crop. McHale have designed an adaptive intake which allows the intake area to automatically adjust for light and heavy crops. This avoids peak loads and results in higher daily throughput regardless of working conditions.

McHale have created their highest output pick-up for the V6760. The new Profi-Flo pick-up has been designed to increase crop intake through more efficient crop flow and has been engineered to ensure end users are operating with a high-performance pick-up that is designed to suit various working conditions.

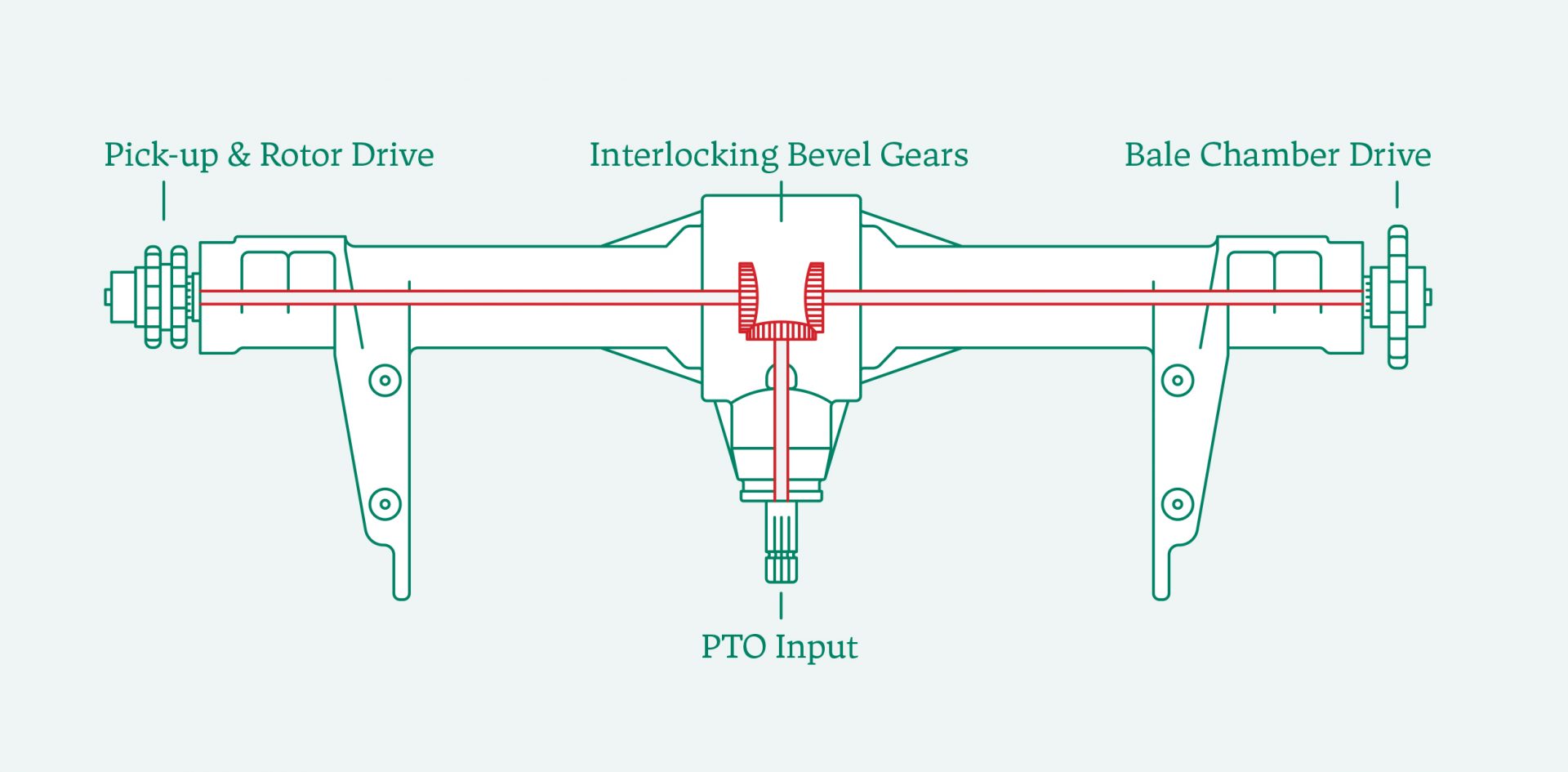

A 540rpm Split Drive Gearbox is fitted to all machines in the McHale Fixed Chamber Range as standard. The gearbox design ensures that power is evenly distributed to both sides of the machine.

The feed rotor or chopping unit boasts a heavy-duty rotor and comb. The flights are welded on both sides for superior strength and on the drive side the rotor is fitted with a double row bearing with a long service life. The star shaped feed rotors ensure a high capacity flow of grass into the bale chamber. The flights on the rotors are laid out in a spiral formation to achieve consistent crop flow. As crop enters the rotor, rotating flights feed the crop to the bale chamber. The flights on the rotor ensure high output, while the star layout reduces the load peaks as the machines work in heavy swaths.

As baling conditions are not always ideal, uneven swaths can occur which can lead to blockages. The McHale variable chamber baler range is fitted with a drop floor unblocking system, which means blockages can be fed through in three simple steps.

Drop the Floor

Should a blockage occur, the sound of the slip clutch alerts the operator, who can hydraulically lower the floor from the tractor cab.

Re-engage the PTO

This widens the feed channel and on re-engaging the PTO, the blockage can be fed through.

Reset the Floor

The floor can then be reset to its original position and baling can resume.

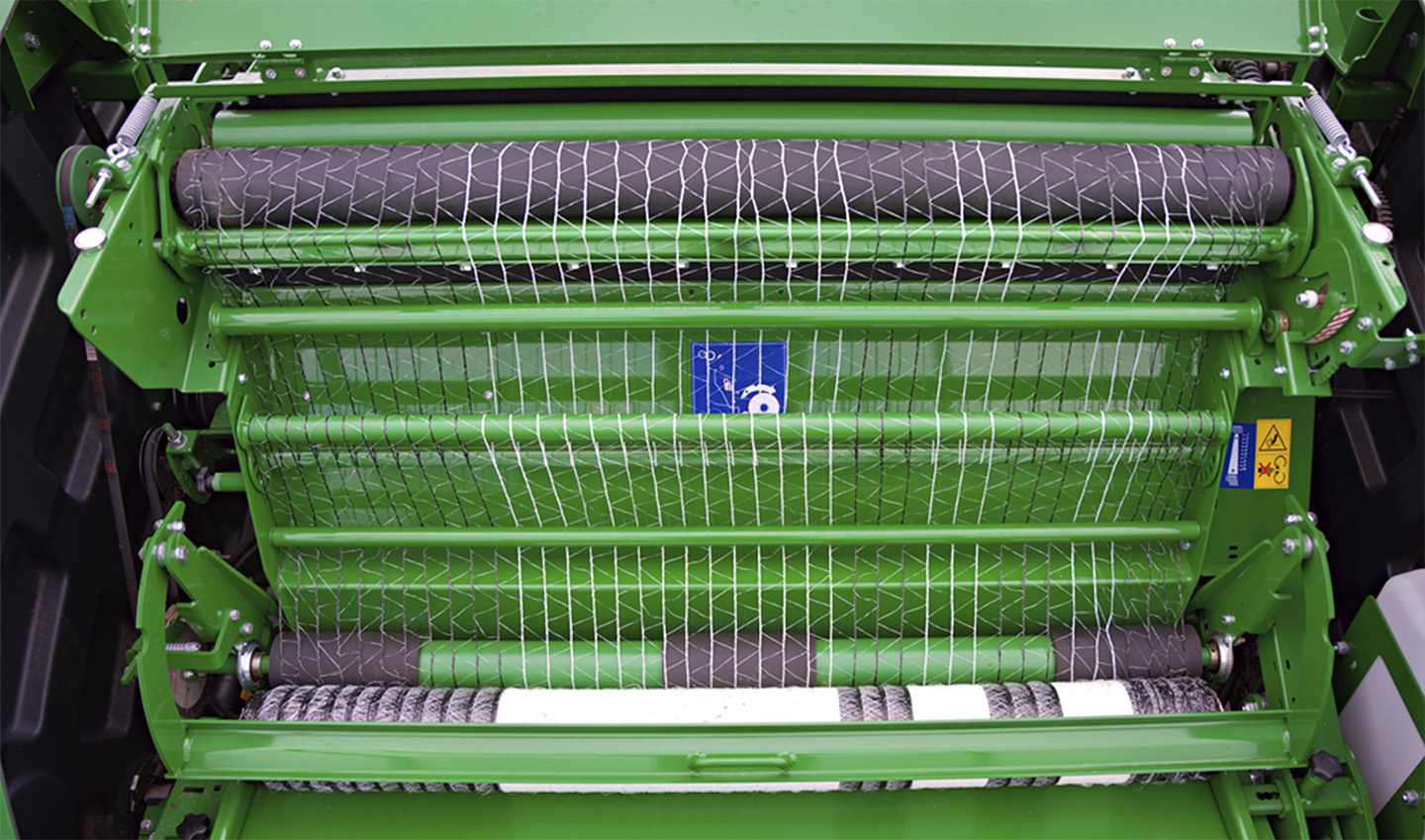

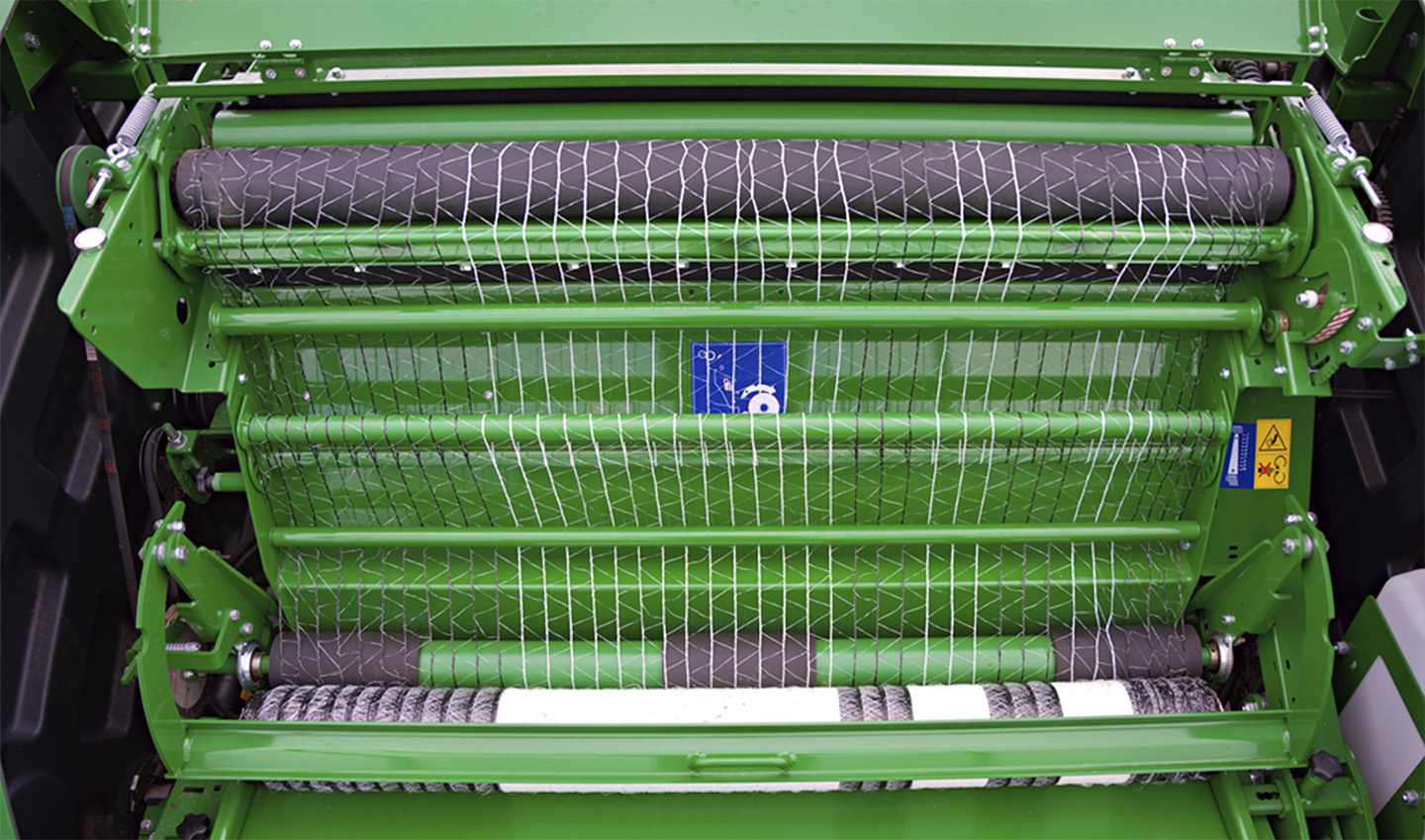

A high performance netter has been designed and developed for the F5-500 range. A Dual Feed Netting System is fitted to all F5-540, F5-550 and F5-560 machines.

Net Tension Application – Each of the simple, yet effective net binding systems apply net to the barrel of the bale. These systems ensure efficient net usage and that a tight layer of net is evenly applied to the bale. The net tension can be adjusted on the machine or control console to suit operator’s requirements depending on the model.

Net Layer – The number of layers of net being used can be easily adjusted as the machine passes through different crop conditions. On the F5-540 and F5-550, by simply moving the net adjustment handle down, more net will be applied, while by moving the handle up, less net can be applied. On all ISOBUS machines, net/film adjustment can be controlled from the control console in the tractor cab.

Specifications

Compare specifications below, to find out what will be suit your operations

| Models | F5-550 | F5-560 | F5-560 Plus |

|---|---|---|---|

| Sort | Baler | ||

| Min. HP Requirement | 90 | 100 | |

| Weight | 3500 kg | 3700 kg | 3850 kg |

| Length | 4.05 m | ||

| Height | 2.45 m | ||

| Width | 2.55 m | ||

| Working Width | 2.1 m | ||

| Knives | 15 | 25 | |

| No. of Rollers | 18 | ||

| Bale Diameter | 1.25 m | ||

| Bale Chamber Width | 1.23 m | ||

| Bale Chamber Feed | 15 Knife Chopper Feed Rotor | 25 Knife Chopper Feed Rotor | |

| Binding Material | Net | Net or Film | |

| Storage | 1 + 1 Storage | ||

| Theor. Chop Length | 65 mm | 46 mm | |

| Unblocking System | Drop Floor | ||

| Knife Protection | Hydraulic | ||

| Compare | |||